historical roots

WHAT SETS US APART

We started at the beginning, delving into the history of playing card’s Chinese roots. Tracing the evolution of its manufacturing process from woodblock prints, chromium lithography printing in the 1800s to modern offset printing. Our goal is to rediscover and perfect these lost arts, integrating them with modern innovations to create playing cards of unparalleled quality.

Most printers know what affects the quality of a card -- humidity, equipment settings, coating. But only Legends cares to use it to our advantage, because we want to print the best, not cheapest, product.

uncompromising quality

INNOVATION AND DETAILS

Constantly staying at the forefront of printing and packaging advances, we seek to apply these to playing card manufacturing.

The LPCC stamp-seal (above) is printed with exquisite detail and perforated for perfect alignment so you can open a deck cleanly without a sticky mess.

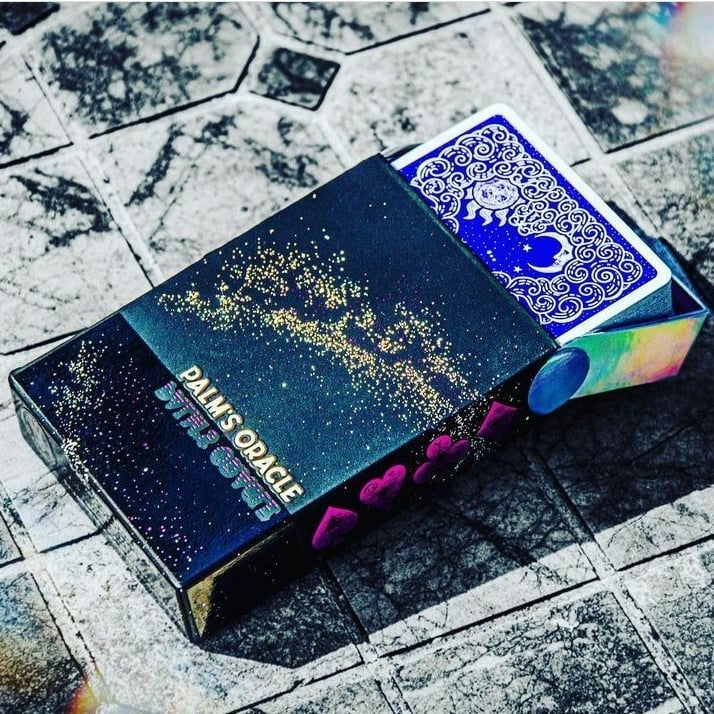

Decks like Palm's Oracle features a matte black soft-touch box with Spot UV accents and an innovative slide-out mechanism with holographic lining! It sounds like a mouthful, but we love extravagant projects. We specialize in the luxury market, with most of our tucks feature deep embossing and striking foil accents.

-

SUPERIOR PAPER

click here to learn more about paper and finishingThe foundation of a playing card. Our card stock is made from sustainably-sourced, imported paper that is thinner, yet stiffer than the competition’s. We are constantly experimenting with new paper stock and tweaking aspects of production to improve handling and offer variation in our range.

Quality and consistency is paramount when dealing with paper, when you print with Legends we will closely match your decks to the feel and durability of any of our in-house decks.

-

A CUT ABOVE

One of our crowning achievements. A closely guarded secret that distinguishes our playing cards from all other brands; the ‘glass like’ edges of our signature ‘Diamond Cut’ process. The edges of our in-house decks feel like they have been buffed smooth, enabling advanced sleight-of-hand techniques like the Faro shuffle to be executed with ease. Expert card handlers instantly recognize the superior feel of a Legends ‘Diamond Cut’ deck of playing cards.

(see above for a comparison between the competition and Legends).

-

FACTORIES AND SUPPLIERS

Legends has a primary factory located near Hong Kong with over 800 support staff, 5 offset printing presses, offline coating and drying, in-house hot foil stamping , and our proprietary "diamond finish" cutting machines and tooling.

Occasionally we will outsource print runs to other countries depending on the customer's needs, in which case we only work with manufacturers who can re-learn the ropes and adhere to our strict quality control. Our production process require new techniques and a willingness to experiment. Once the right fit comes along, we build strong relationships with owners and management. Every step of the printing and design process must be managed to our standards.

-

THE MAGIC INGREDIENT

The finishing touch. Playing cards without coating aren’t really cards, they are just rough paper stock and unusable in card play. Traditionally cards were coated in varnish or waxy substances to aid in handling. These formulas are closely guarded secrets which take years to perfect.

The Legend's coating was created to produce a slip factor that isn’t too slick as to make shuffling difficult, yet easy to spread between the hands. This coating also improves as the cards are handled, a rare quality reminiscent of Jerry’s Nugget’s, which sell for over $300 per deck.Print with the best, play with the best. Only with LEGENDS.